Advanced Warehouse Management is designed for larger distribution facilities, fulfilment houses, etc.

For example, those businesses that require semi-automated stock replenishment for order packing lines.

Warehousing is primarily concerned with the allocation of stock to specific bins within a location, and the total tracking of that stock, from the moment of arrival in the warehouse through every stage to final dispatch. Although primarily concerned with stock movement, warehousing is evident throughout Jim2 as stock transactions are tracked through the system.

While having individual stock allocated to a specific bin is important, that doesn't necessarily constitute an efficient warehouse. Jim2 Warehouse Management recognises primary picking bins, reserves and bulk stock. Warehouse Management saves considerable time by evaluating job requirements, and suggesting the best bin to pick stock from. During the course of operations, stock consumed from the primary picking bins needs to be replenished and, when in stock transfer mode, Jim2 will nominate the preferred bin from which to transfer stock.

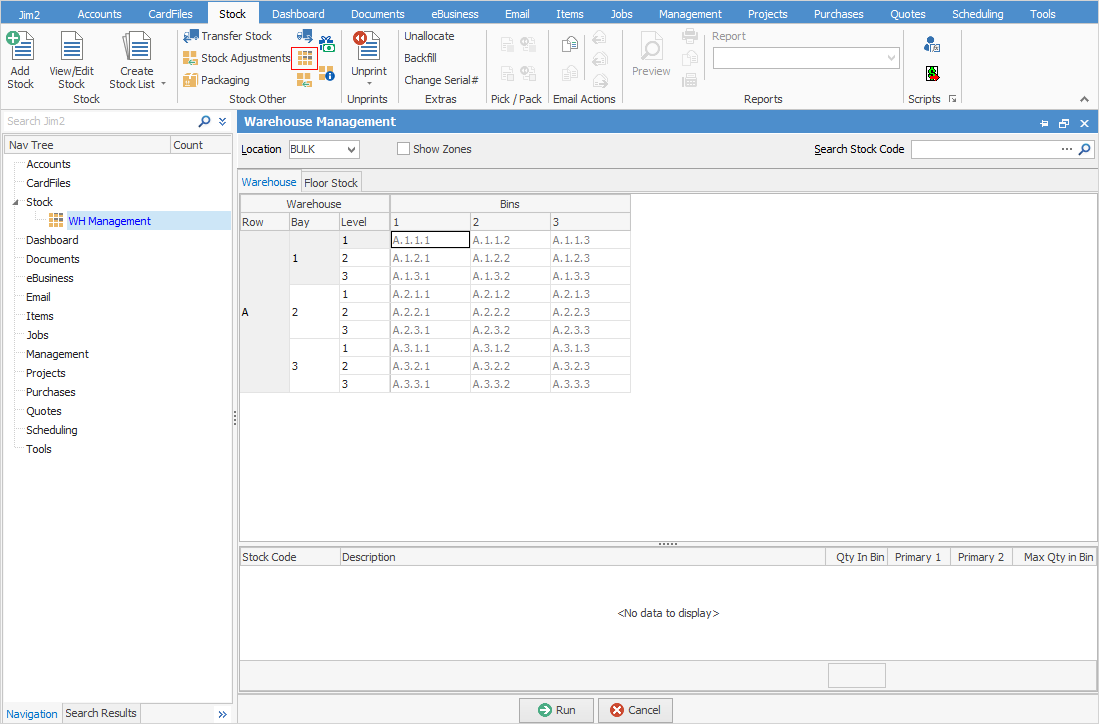

Stock management is assisted by a visual display of the warehouse, indicating what stock is allocated to individual bins, including bins that may be temporarily empty. Warehouse Management is a graphical interface within the stock object that enables viewing the physical layout of the warehouse at a glance, and the position of stock bins.

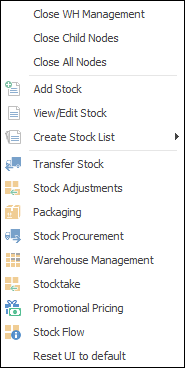

Right click options in Nav Tree

After the top 3 (which are self explanatory), these options mirror what is on the ribbon in the Stock tab, except for the last tab, which will reset all tabs to the default.

Further information