The core component of Warehousing is the synergy of your physical warehouse and Jim2. This happens as a two-fold process:

▪identifying the layout of your storage area in Jim2 through stock bins; and

▪setting up workflow processes as in Warehouse Management and your business procedures.

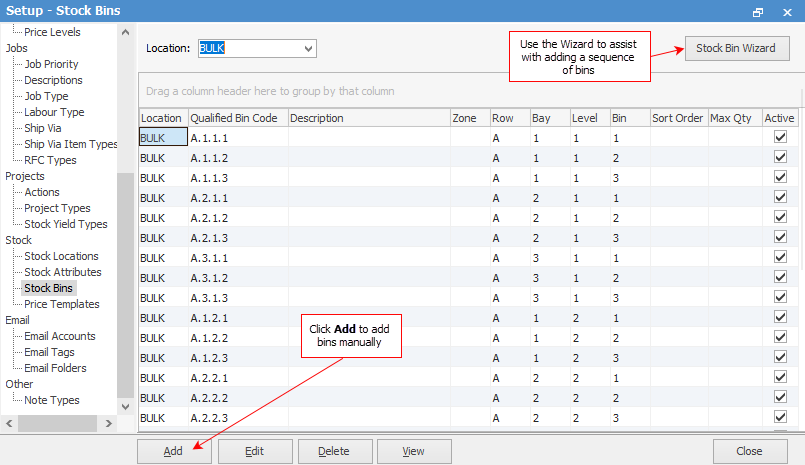

Bins can be added in two ways:

1.Manually – typically used for making minor changes/additions to your warehouse.

2.Using the Stock Bin Wizard – typically for the initial setup of your warehouse, or for large additions.

On the ribbon, go to Tools > Setups > Stock > Stock Bins.

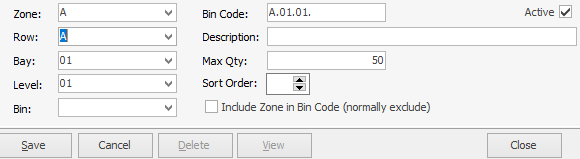

1.Add Bins Manually

▪Enter the zone, if used.

▪Enter the appropriate row, bay, level and bin numbers (mandatory fields) – a qualified bin code will appear in the Bin Code field. An optional bin description can be included.

▪Select the Sort Order if required.

▪If using Zones, the zone can be optionally included in the Bin Code.

▪Max Qty allows you to enter the maximum quantity that will fit in the bin.

▪Active: ticked means this bin is being used. Unticked means this bin is not being used.

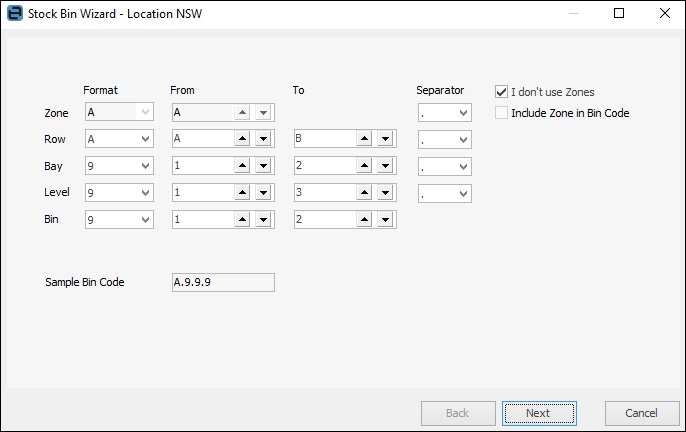

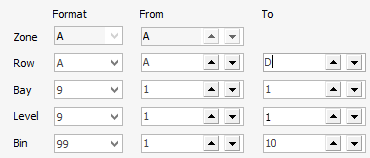

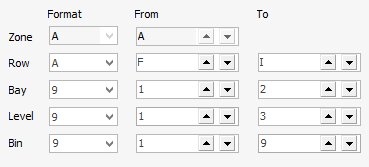

▪This virtually follows the same process as in 1 above, except that you have a choice of format and separator style.

▪Enter the starting and ending number for each row, bay, level and bin.

▪Use the two tick box options as appropriate.

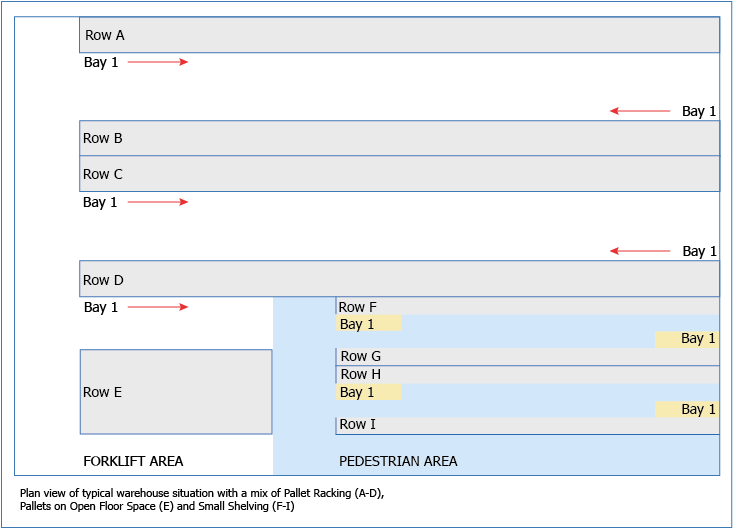

Warehouse Layout – A Practical Example

1.As shown in the example above, the Stock Wizard was used to create Rows A to D,

then

2.Rows F to I (the shelving) were created, again using the wizard, with these settings below:

and finally:

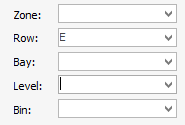

3.Row E (the floor space) was created by clicking Add to open the Add Bin screen and typing E into the Row field.

See Also: