Estimating quantities for stock procurement can be completed by using a nominated minimum quantity required, a calculated quantity to meet the requirements of a stated number of days, or a comparison of the two methods, with the higher unit calculation being used to create the resulting purchase order.

To combine both methods for nominated stock codes, enter a minimum required quantity and the number of days supply required.

Days Supply method

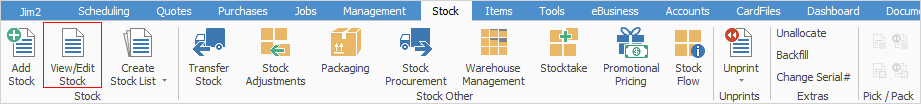

1.On the ribbon go to Stock > View/Edit Stock.

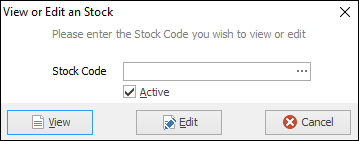

2.Either enter the stock code to view or edit, or click the ellipsis (...) to open the Stock Select screen and locate the stock code from there.

3.When the correct stock code is on screen, click Edit, then go to the Locations tab at the top left of the screen.

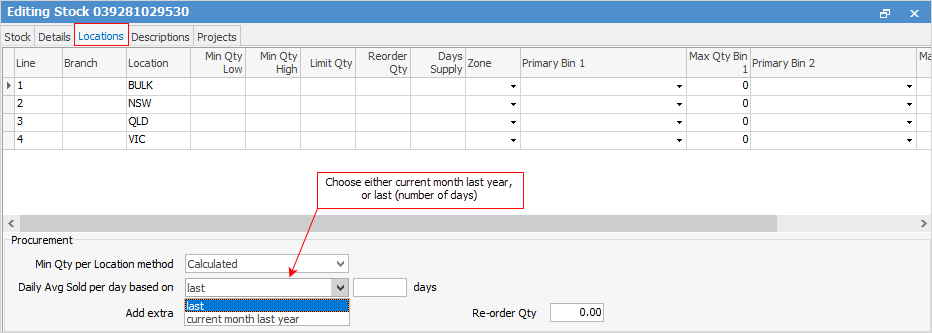

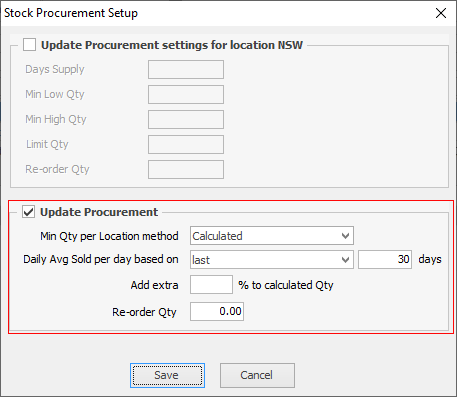

4.Move to the Min Qty per Location method field and select Calculated (choices are Calculated or None).

5.In the field Daily Avg Sold per day based on, choose either current month last year, or last (days), and nominate how many days. Note that days include weekends when 7 days or over.

6.If applicable, enter a number to the Add extra % to calculated Qty field. This will have the effect of a loading, ie. increase the quantity ordered by this percentage.

7.Enter the Reorder Qty.

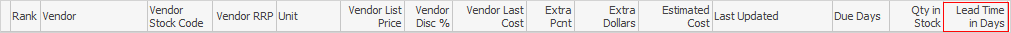

8.In the Vendors tab at the bottom of the screen, there is a column/field called Lead Time in Days, which is used to tell Jim2 how long it takes for delivery of this stock from the nominated vendor. Accurate lead times are particularly important when using the Days Supply Stock Procurement method.

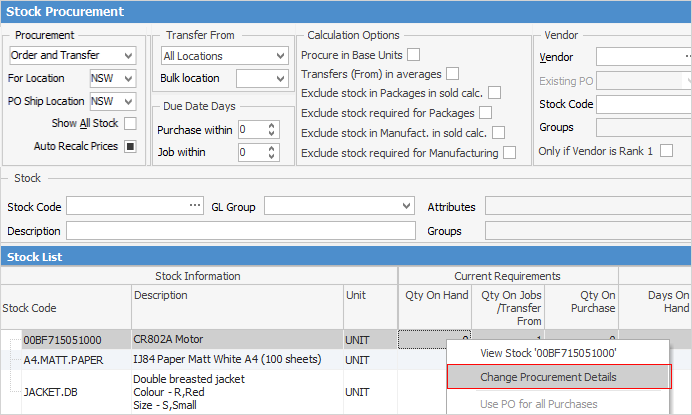

Stock procurement can also be used to update a list of stock in the grid. Select all stock within the grid, right click and select Change Procurement Details.

Enter preferences here:

Further information