The purpose of a stock’s minimum low/high values is to provide a sliding window for ordering stock using Stock Procurement. For example, where min low is 5 and min high is 10. Once the stock on hand (SOH) quantity drops below 5, Stock Procurement will ensure that enough will be purchased to bring the SOH up to at least the minimum high quantity of 10.

Estimating quantities for Stock Procurement can be completed using a nominated minimum quantity required, a calculated quantity to meet the requirements of a stated number of days, or a comparison of the two methods, with the higher unit calculation being used to create the resulting purchase order.

The Min Qty Low and Min Qty High procurement parameters provide a window for purchasing, and provide a way of batching orders rather than ordering the same stock every day.

Basically, you are saying you wish to keep between 5 and 10 of this item in stock. When the stock level drops to 5 or below, then you wish to purchase enough stock to bring the level up to 10.

Both parameters are optional, in which case they are not used and the procurement order quantity is calculated based purely on how many days’ worth of stock you wish to maintain.

If you want to combine both methods for nominated stock codes, simply enter a minimum required quantity, and the number of days supply required.

|

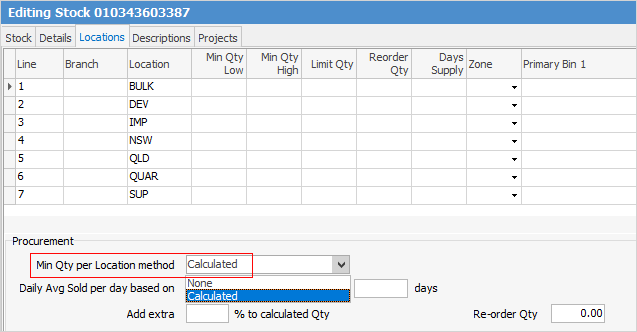

Note: Within the stock code, on the Locations tab in the header, Min Qty per Location method must be set to Calculated (this is normally the default). If this is set to None, that stock will not be used in a Stock Procurement session.

|

Min Qty Method

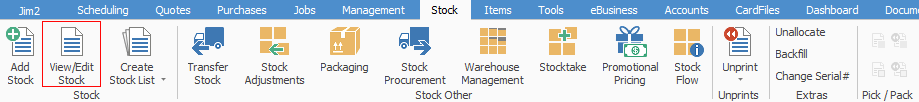

1.On the ribbon go to Stock > View/Edit Stock.

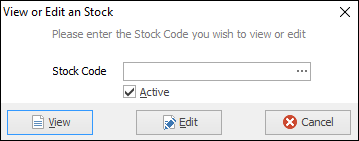

2.Either enter the stock code that you want to view or edit, or select the ellipsis [...] to open the Stock Select screen and locate the stock code from there.

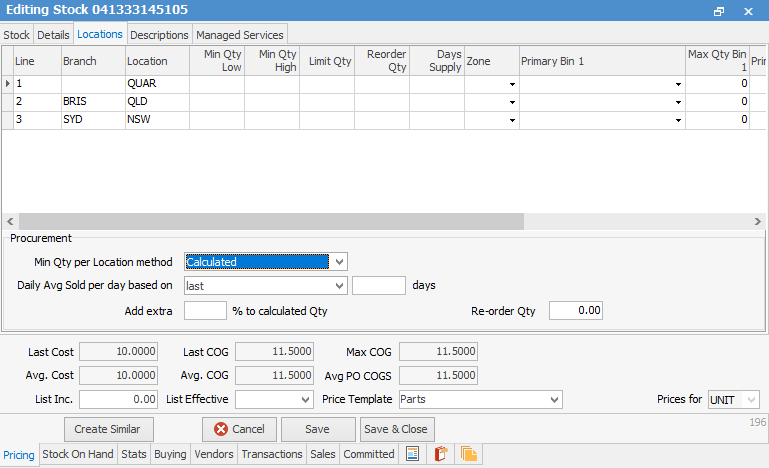

3.When the correct stock code is shown, click Edit to open the Editing Stock screen, then click the Locations tab at the top left of the screen.

4.Move to the Min Qty per Location method field and select Calculated.

5.For each required location, enter a minimum quantity in base units (ie. Unit Measure 1 Terms) in the various fields, Min Qty Low, Min Qty High, etc.

6.If applicable, enter a reorder quantity for the stock code. This would most likely be the preferred minimum order required by the vendor.

7.If applicable, enter a number to the Add extra % Qty field. This will have the effect of a loading.

8.When finished, click Save or Save & Close.

Limit Qty

Limit Qty provides a way of putting an absolute limit on how much stock you wish to order. This is useful when average usage gets thrown out because of one-off bulk sales, catalogue sales and promotions, and seasonal peaks, etc.

The Limit Qty parameter is optional, meaning, if left empty there is no limit on how much stock can be ordered.

Reorder Qty

Reorder Qty can be at a stock or stock location level. If a location level reorder quantity is specified it will be used, otherwise the stock’s default reorder quantity will be used. Either way, both parameters are optional.

Days Supply

Days Supply allows users to specify how many days’ worth of this stock they wish to purchase or transfer, based on average usage.

Further information: