There are two ways refurbishment can be handled in Jim2:

1.Acquiring the second hand unit into stock, and invoicing it back out using a kit to include additional consumables, spare parts and labour.

2.Acquiring the second hand unit into stock, and re-manufacturing it into a refurbished product, with accurate COGS including additional consumables, spare parts and labour.

The following covers point 2 above.

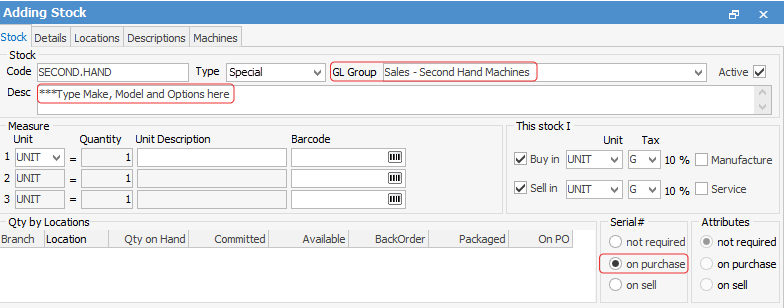

Set up a separate Stock GL Group from the finished goods general ledger's for stock on hand, COGS and income.

This example assumes the general ledger will be a Sales general ledger. It may be preferable for it to instead be a Service general ledger

Set up the stock code that will deal with all incoming second hand machines, regardless of condition.

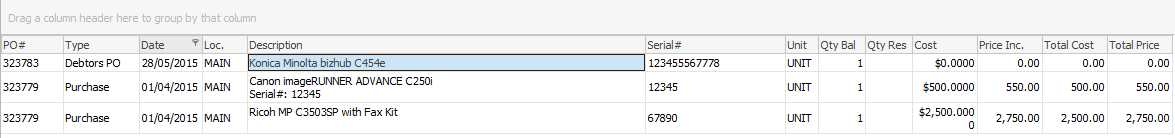

When the stock is acquired, use the Stats tab at the bottom to identify which unit to use for the customer, which shows the custom description of the individual machines, as well as their serial numbers.

As see from the above example, one unit was brought in for $0 directly from the customer at the end of a contract, and a Debtor's PO was used to purchase the stock. This also allows for providing the customer with a credit for a trade-in, which can then be applied to the invoice for the replacement goods.

The other two were purchased from a vendor or wholesaler on a regular purchase order with differing costs.

To use method 2 to sell the copier back out to a customer, put the unit through a manufacturing process, which will capture all costs, remove the base unit, consumables and spare parts from stock, and add into stock a refurbished unit with the combined costs of all of the components.

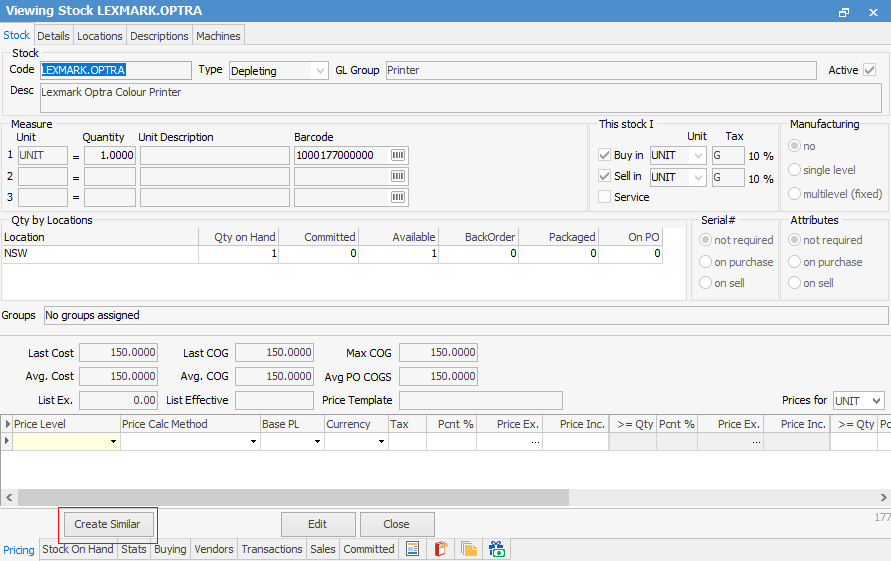

To get started find the existing finished goods stock code and Create Similar from it:

Go with the default Create Similar options, then edit the Stock Code, GL Group, Stock Group and Vendor tab.

Stock code should be something like LEXMARK.OPTRA.R (R at the end to identify it is a refurbishment stock) GL Group should be the Sales – Second Hand Machines general ledger created above Stock Group should be Second Hand Machines or similar the details in the Vendor tab should all be removed, as these 'R' codes are not purchased – they are manufactured instead.

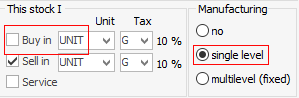

Tick Manufacture under This stock I to the right of the stock code to advise Jim2 that these products will be manufactured. Jim2 will untick Buy automatically.

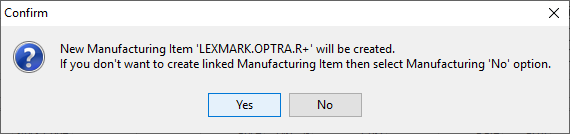

Jim2 will automatically create a Manufacturing Item. Click Yes to continue, noting down the Item code.

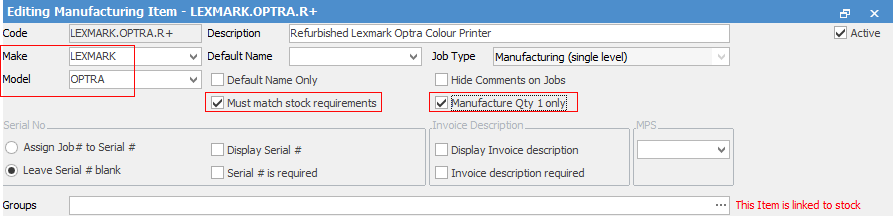

Now look up Item LEXMARK.OPTRA.R+ and edit it. Several checkboxes need to be changed from the defaults. Enter the Make and Model, and change the checkboxes for Manufacture Qty 1 only, and Must match stock requirements.

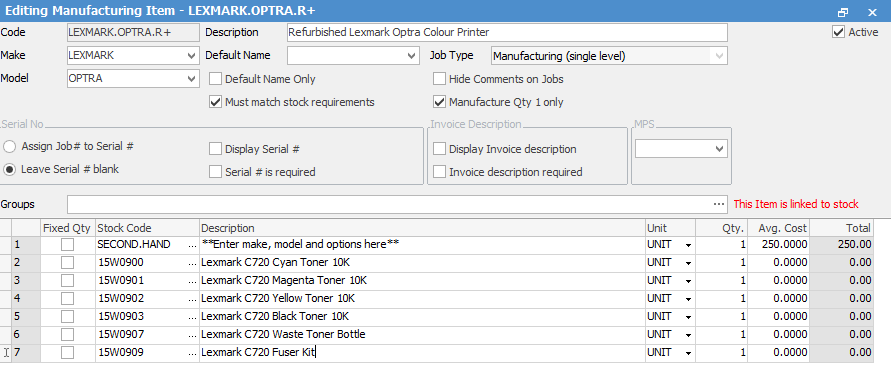

Now, configure the Manufacturing Item to specify which components should be added to every refurbishment job for this model. This is configured from the Stock tab at the bottom left on the Item.

Whilst just the base SECOND.HAND stock code can just be added, it is recommended to add all standard replacement stock for that model.

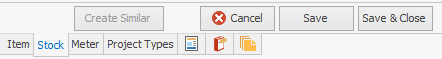

Save the Item and now have everything is ready to re-manufacture LEXMARK.OPTRA.R+ products from a SECOND.HAND stock code.

To create the job to re-manufacture the product, do the following:

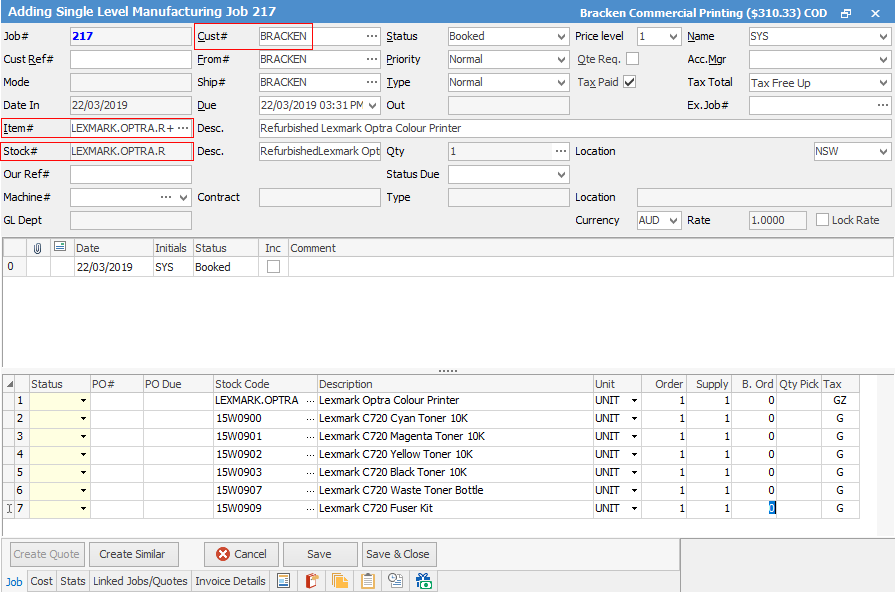

1.Go to the Jobs tab and add a new job.

2.Set the Cust# to company cardfile.

3.Set the Item to the Manufacturing Item created above, e.g. LEXMARK.OPTRA.R+.

4.The stock from the Manufacturing Item loads onto the job automatically when pressing Enter.

5.Select the serial number of the second hand stock code to choose which base unit to re-manufacture.

6.Select the serial number to be manufactured in the Stock Description field next to the stock code. This should be the same as the base unit.

7.Add any spare parts or consumables not listed to the job. Remove anything listed by default that isn't required.

8.Add the technician's labour, as for any service job.

9.Once everything is updated, set the status to Finish and click Manufacture Job on the ribbon.

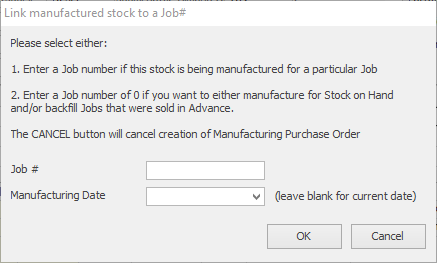

10.Jim2 prompts to link the manufactured stock to an existing Job#. If there is no existing Job#, enter 0 to add it to stock, and click OK.

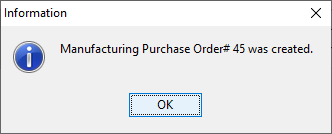

11.Jim2 will advise if it successfully created the manufacturing purchase order to bring the new product into stock:

12.Check the stock levels of the base unit SECOND.HAND and the associated spare parts and consumables to see they have all been depleted. Check the LEXMARK.OPTRA.R stock code to see have the refurbished stock is now on hand. View its costs in the Buying tab.

13.Sell this stock on a job as normal.

Alternatively, refurbish using special stock and a sales kit.

Further Information

Refurbish Contracts Using Special Stock and Sales Kit