An Item, which is used only in jobs, quotes and projects, is used for three purposes:

1.To display the actual stock object information, along with make and model that is being sold, serviced or repaired (eg. specific type/brand, make and model of a pump).

2.To display the category of work being carried out (eg. onsite, rework).

3.To store a bill of materials for products that are manufactured.

This section explains the function of Items within the work process, and the interaction of other Jim2 objects in managing the information maintained within an Item. The Item in a job interacts with the stock and can be assigned as the responsibility of single or multiple user(s). See below for an example.

|

For Jim2 Managed Print Services Edition, please view Items here for extra information specific to Managed Print Services. |

An Item is used as a means of automating various functions within the system, including tracking and reporting. An Item can be set up with related stock, so the user is prompted to add the related stock to a job.

The Item describes what is to be serviced in a service job, what is to be manufactured in a manufacturing job, and what sort of sales job is to be executed.

One job is added for each Item entering the workflow. A list of Items the company uses will show areas of competence – selling, servicing or manufacturing each Item.

|

Be careful not to confuse stock with Items. An Item represents the prime objective of a job, ie. the method of sale, service, etc.

If an Item can be identified as applicable to both sales and service jobs, add that Item as a Sales Item as well as a Service Item, ie. add two Items (with different names) using each type. |

The following example is for a computer sales and service company as a working example of Items.

This company has various sales methods (Items), including door-to-door, by telephone, over the counter and via the web. They also manufacture computers from multiple parts, and their service division services computers, hard disk drives and monitors. Therefore, their workflow involves selling a computer, manufacturing a computer and servicing a computer.

How they make the sale is a Sales Item, what they manufacture parts into is a Manufacturing Item and what they service is a Service Item.

If the company wanted to track how they sell stock, they would create an Item code for each sale method, eg. Sale.Door would represent all door-to-door sales jobs.

As for servicing, they may want to have different procedures for servicing a range of computers. In this case they would create an Item code for each computer in the range, eg. SYS.IBM would represent an IBM computer.

|

It is important to choose Item codes carefully. Consider what sort of Items pass through the workflow, and how to differentiate between them in a meaningful way. |

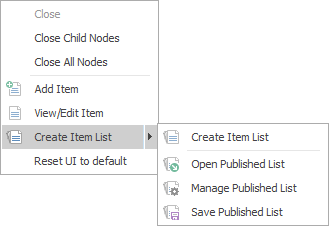

Right click options in the Nav Tree

After the top 3 (which are self explanatory), these options mirror what is on the ribbon in the Items tab, except for the last tab, which will reset all tabs to default.

Further information

Factor a Procedure with 3rd Party Debtor Finance

Give a Customer a Permanent Discount

Pay Commission to a Contractor