|

On this page, two separate Jim2 objects, Items and Stock, will be discussed. Be sure not to confuse an Item with a stock item. |

To create a Manufacturing Item, first create manufacturing stock, which will then create the manufacturing Item automatically, using the same code as the stock with a plus (+) sign at the end of the stock code. This is to avoid double-ups with service stock that creates an Item, as there may be stock that can be sold, serviced and manufactured.

See Manufacturing for an explanation of single level and multilevel (fixed cost) manufacturing.

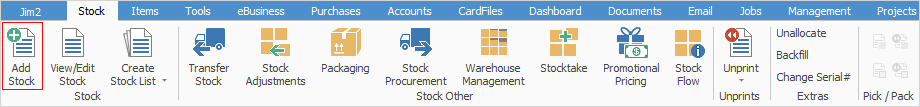

1.To begin creating a new manufacturing Item, go to Stock > Add Stock on the ribbon.

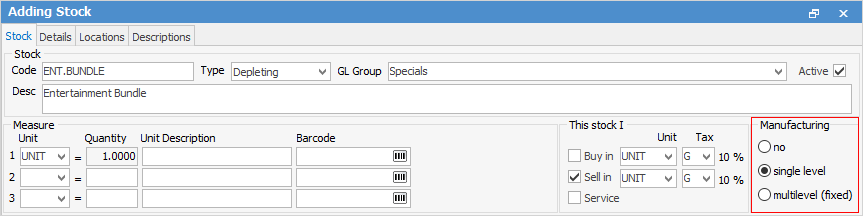

2.Enter a stock code, description, type and GL Group for this new stock, then tick Manufacturing, as required.

3.Click Save, then select Yes to the question Are stock details correct?

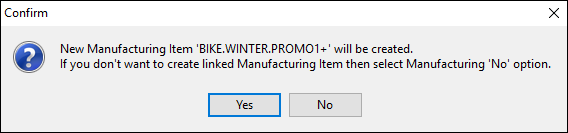

4.Because the Manufacturing box has been ticked, a message will appear to confirm creating a new manufacturing Item.

5.Click Yes and the manufacturing Item will be created. The manufacturing Item code is the manufacturing stock code with a plus (+) sign at the end.

|

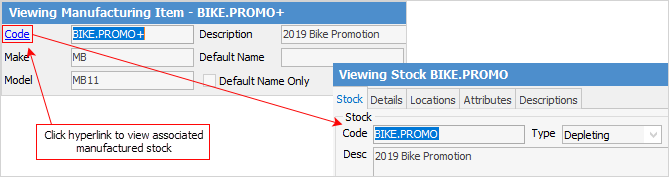

Once the new manufacturing stock and manufacturing Item have been created, there will be a hyperlink to the manufacturing Item record from the stock code and back again from the Item code to the manufacturing stock record.

|

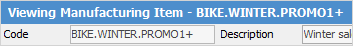

6.The associated manufacturing Item will then open. The header is shown here.

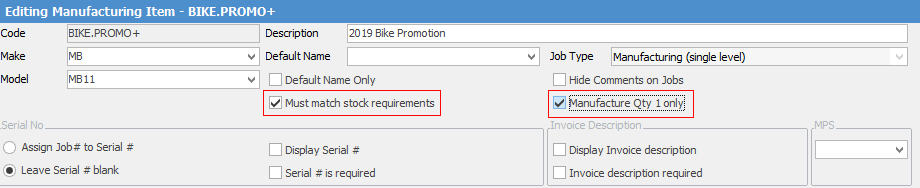

There are two checkboxes in the Item header which are specifically for MANUFACTURING Items, and are not displayed on sales or service Item records.

Checkbox |

Purpose |

|---|---|

Must match stock requirements |

When manufacturing this Item, the requirements set up within the manufacturing Item must be fully available. If a Manufacturing Item requires a quantity 4 of a particular type of stock, it cannot be manufactured until the entire quantity of 4 is available. Similarly, if labour is 2 hours, 2 hours and 4 minutes cannot be entered. |

Manufacture Qty 1 only |

When manufacturing this Item/stock only manufacture a quantity of 1 per job. |

The stock required to manufacture this Item is added via the Stock tab of this manufacturing Item.

|

The order of stock added to a manufacturing job is the same as it is on the manufacturing Item. |

Stock on manufacturing Items includes a Fixed Qty checkbox. Ticking this box will keep that stock's quantity the same, regardless of quantity of stock being manufactured. This is useful for stock like Machine Setup, where there is only one machine setup per manufacturing job regardless of the quantity of stock being manufactured.

|

Once a manufactured stock has transactions against it, its stock type cannot be changed to be non-manufactured.

If manufacturing stock is marked as inactive, a prompt will appear asking to set the linked manufacturing Item to inactive if desired. |

Further information

Kitting v Packaging v Manufacturing

How to

Add Stock to a Manufacturing Item

Add Single Level Manufacturing StockAuto Create Manufacturing Jobs and POs

Include Labour in Cost When Manufacturing