Another type of purchase order is a Manufacturing purchase order. This is created from a manufacturing job when it is manufactured. A purchase order cannot be added if the Type is Manufacturing.

The following relates to single level manufacturing. See Set up and Use Multi-Level Manufacturing for information on multilevel (fixed cost) manufacturing.

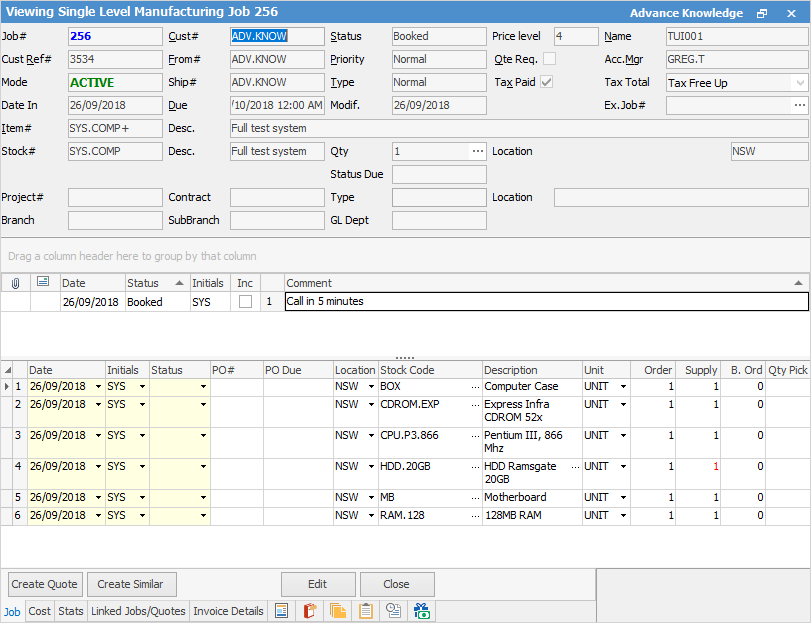

Manufacturing job

|

Some letters in the field names within the header are underlined, eg. Cust#. Using Alt+ the underlined letter will jump to the field beside that heading. |

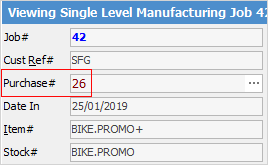

Once the job has been manufactured, the Invoice# field shows the Purchase# field. Click the ellipsis [...] to open to the Manufacturing purchase order.

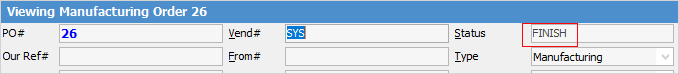

When a manufacturing purchase order is created, it will automatically have the status of Finish.

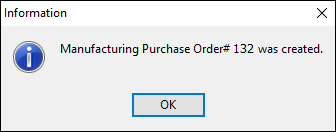

Manufacturing order created.

Manufacturing purchase orders will have the tax code X, as they are not included in the BAS GST Report.

Expense orders can be applied to manufacturing purchase orders.

|

Click the grey ellipsis [...] in the Job# field which will open the manufacturing job (eg. Job# 220 in top image). |

COGS movements in relation to manufacturing stock

The Price field will show the raw material cost – depleting and special stock.

Cost of goods is the raw material cost plus labour and/or applies costing to be used in pricing structure.

The purchase orders created from manufacturing jobs take the COGS value for the depleting and special stock included in manufacturing that product and moves it from their Stock On Hand Asset accounts to the Manufacturing Stock – Stock On Hand Asset account.

Unprint manufacturing purchase orders

The manufacturing purchase order can only be unprinted from the manufacturing job – this cannot be performed through Unprint in the Purchases screen.

If the manufacturing job is unprinted, the manufacturing purchase order status will be changed to Cancel and the stock grid will be cleared. The purchase type will stay as a Manufacturing Purchase so you can re-use that purchase order to re-manufacture that job.

Assigning a job number to a manufacturing purchase order

When the Manufacturing purchase order is being created, there is the option of assigning a job number to that manufactured product(s).

As manufacturing stock can be sold in advance, it can be manufactured for a specific job/customer without automatically backfilling any sold in advance. There is only one opportunity to assign the job number – when choosing to manufacture the job, a job number field will be displayed. Enter the related job number here.

Unlike single level manufacturing, the cost of multilevel manufactured stock is fixed and set on the manufacturing job. It is not updated when finishing purchase or expense orders of stock used in the manufacturing process, unlike single level manufacturing. Once the multilevel (fixed cost) stock is manufactured, its cost will not be affected by expense orders, thus enabling the stock codes to be used as parts in another manufacturing job.

Further information

Kitting v Packaging v Manufacturing

How to

Add Stock to a Manufacturing Item

Add Single Level Manufacturing Stock

Auto Create Manufacturing Jobs and POs

Include Labour in Cost When Manufacturing