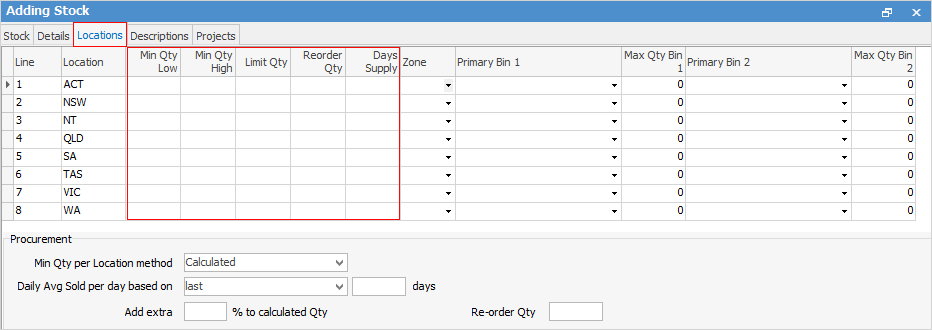

This tab is used to show the location where stock is stored at. The stock locations and bins are added via Tools > Setups > Stock Locations and Stock Bins tabs.

if using Stock Procurement for auto reordering, set up minimum quantity and reorder quantity requirements here.

|

Stock can be held in multiple locations, but only one bin per location. |

Area |

Field |

Explanation |

|---|---|---|

Locations Whilst zones and bins only relate to Advanced Warehousing, nominate one bin for storing stock.

|

Line |

The line number of this table. |

Branch |

The branch the stock is located at (if using branches). |

|

Location |

The physical location of the stock. |

|

Min Qty Low/Min Qty High |

The quantity that required to be kept in stock at all times, in addition to job/transfer requirements. |

|

Limit Qty |

The maximum quantity that can be ordered at any one time. |

|

ReorderQty |

The minimum cost effective quantity to be ordered, eg. always order ten at a time, as they are only half the price when ordered this way. This is at location level. |

|

Days Supply |

The number of days worth of this stock to keep in stock. |

|

Zone |

Zone/area. |

|

Primary Bin 1 |

First picking bin. |

|

Max Qty Bin 1 |

Maximum quantity for first picking bin. |

|

Primary Bin 2 |

Second picking bin. |

|

Max Qty Bin 2 |

Maximum quantity for second picking bin. |

|

Procurement These options are only shown if the stock type is depleting, and these settings are the default for all locations. |

Min Qty per Location method |

Dropdown list: choose from None or Calculated. The fields shown above (highlighted in above image) are not displayed if None is selected.

Selecting None means that this stock will not be included in a Stock Procurement session.

Selecting Calculated will show this stock in a Stock Procurement session. |

Daily Avg Sold per day based on |

drop down list. Choose from current month last year or last (number of days). If Last is selected, enter the number of days in the next field (days). |

|

Add extra … % to calculated Qty |

Add a percentage to act as a safety buffer, in case the calculated quantity is insufficient to cover sales campaigns, promotions, etc. |

|

Reorder Qty |

Global reorder quantity for all locations (overrides calculated quantities). |

|

The reorder quantity should be the unit count – not the multiple unit measure for This Stock I Buy. If the stock is typically This Stock I Buy in DOZEN (multiple unit measure = 12 units), the reorder should be in multiples of 12. When raising a purchase order for this stock, Jim2 will calculate how many dozen to order (eg. if reorder is set to 48, when raising a purchase order it will automatically choose 4 DOZ). |

Further information