Manufactured stock is stock that your business makes itself, ie. fabricates from the ground up, assembles from purchased components, creates by other methods, etc.

Internal logic rules within Jim2 help businesses to manage the production of manufactured stock. The manufacturing process in Jim2 involves:

a)The stock code that is to be manufactured.

b)The stock codes used in the manufacture process, including parts and labour.

c)A manufacturing Item, which is where the Bill of Materials is stored.

d)A manufacturing job, which is where the stock codes in point b) are consumed and manufactured into point a). The consumed stock codes in point b) are no longer available for jobs. The manufacturing job also records the actual labour used.

Jim2 supports two methods of manufacturing: Single level manufacturing, and multilevel manufacturing.

Single Level vs Multilevel

Manufacturing Method |

Details |

Single Level |

•Finished manufactured product put into stock on hand at exact cost of included parts (and labour, if configured via Options). •Any additional costs related to parts/stock used (from finished PO or expense order, etc.) are also included in manufactured stock SOH cost, and flow through to COGS if stock sold. •Must be the final manufactured product •Can include parts/stock that are produced via multilevel manufacturing. |

Multilevel |

•Finished manufactured product put into stock on hand at fixed cost at point of manufacture. •The cost difference between the fixed cost and actual costs of parts and labour are offset to the linked Fixed Cost Offset GL Account. •Any additional costs related to parts/stock used (from finished PO or expense order, etc.) are offset to the linked Fixed Cost Offset GL Account. •Can be used in other manufacturing processes, including single level. |

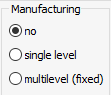

Consider what components are used to make a final product before selecting the Single Level or Multilevel (fixed cost) manufacturing type from the options in the stock area of the header. Once a manufacturing type is set for a stock code, it cannot be amended.

Button |

Explanation |

no |

This stock record is not manufactured. |

single level |

The stock record is single level manufactured. Stock record A + stock record B = stock record C as a manufactured product. |

multilevel (fixed) |

The stock record is multilevel. Stock C from above is used in a further manufactured, ie. stock record C + D = stock record E, and so on. |

|

You can only manufacture whole quantities, ie. you cannot manufacture, say, 4.5 of something. |

Single Level Manufacturing

Single level manufactured stock is made up of Stock A + Stock B = Stock C.

Selecting a single level manufacturing option ensures that components are used to make a single final product. You cannot choose a stock using single level manufacture in Jim2 as an ingredient in another manufacturing process in Jim2, ie. you cannot use the finished product as a component of a further product.

▪You can buy manufacturing stock as well as manufacture it if required.

▪Single Level Manufacturing creates a Journal as it removes the components out of the balance sheet, and puts the manufactured stock into the balance sheet.

▪It's difficult to break up this type of manufactured stock. You can unprint, but only if you haven't sold any from the manufactured job.

▪You cannot return a component.

▪Stock costings include labour (not at a GL level for labour).

▪Pricing rules can be based on Cost +.

▪Pricing of single level manufactured stock varies depending on the cost of raw materials.

▪You cannot change the stock type once manufactured stock has been used.

Multilevel Manufacturing

Multilevel manufactured stock is made up of Stock A + Stock B = Stock C at a fixed cost, then Stock C + Stock D = Stock E.

Selecting a multilevel manufacturing option enables you to choose already manufactured stock (fixed cost) as a further ingredient in your manufacturing process, ie. you can use a finished product as a component to manufacture a further product, and so on, to produce the finished product.

This is possible because the cost of manufactured stock is fixed and set on the manufacturing job. It is not updated when finishing purchase or expense orders of stock used in the manufacturing process, as compared to single level manufacturing.

▪When selecting multilevel (fixed cost), you can set the default Manufacturing Cost in the Details tab on the Stock screen.

▪Jim2 uses a Fixed Cost Offset account in your general ledger to account for the difference in cost between the actual costs and the set fixed cost. When completing a Manufacturing job by moving to Finish status and selecting the Manufacture icon from the ribbon, the Fixed Cost Offset account will show the difference between the fixed cost set on the job, and the actual cost of the stock codes used. For example, if all stock codes used in manufacturing are from purchase orders on Received, then the full cost will be offset. When purchase orders are set to Finish, Jim2 will reduce the offset account by the cost of the stock.

▪Labour is considered as a cost of manufacture. Instructions for setting this up are explained in the How To section: Set up and Use Multi-Level Manufacturing.

▪You can manufacture unlimited levels of multilevel manufactured stock.

▪Pricing of a multilevel (fixed cost) manufactured stock does not fluctuate with changes in material and labour costs.

▪The last level of a manufactured stock can use either option: multilevel or single level manufacturing.

An important difference, compared to single level manufacturing is, once the fixed cost stock is manufactured, its cost will not be affected by expense orders, thus enabling the stock codes to be used as parts in another manufacturing job.

The Manufacturing process in Jim2 involves:

a)The stock code that is to be manufactured.

b)The stock codes used in the manufacture process, including parts and labour.

c)A manufacturing Item, which is where the Bill of Materials is stored.

d)A manufacturing job, which is where the stock codes in point b) are consumed and manufactured into point a). The consumed stock codes in point b) are no longer available for jobs. The manufacturing job also records the actual labour used.

Bill of Materials Manufacturing

▪Build BOM’s that can include depleting, non-depleting, special stock and labour to calculate the true cost of production.

▪Set realistic due dates and process status on your manufacturing jobs, and use Create Similar for cyclical manufacturing.

▪When looking up stock, uncover quantity count by location and number of units pending (in manufacture).

▪On completion of the manufacture process, you can choose to adjust final number of successful units before committing count to stock on hand.

▪On Manufacture Jim2 will automatically take the COGS value for any depleting and special stock included in manufacturing that product and move it from (raw material) Stock On Hand asset accounts, to the (complete product) Manufactured Stock – Stock On Hand asset account.

|

Once a part has been single-level manufactured, it cannot be used in another single level manufactured part. |

Further information:

Add Single Level Manufacturing Stock

Include Labour in Cost When Manufacturing

Kitting v Packaging v Manufacturing

Set up and use Multi-level Manufacturing