Multi-level manufacturing is available via the use of fixed costs within the manufacture process.

Setup

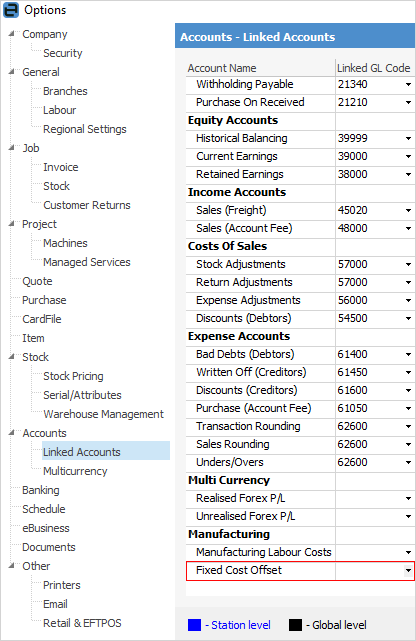

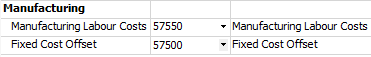

For fixed cost manufacturing, a linked GL account is required. On the ribbon, go to Tools > Options > Accounts > Linked Accounts.

|

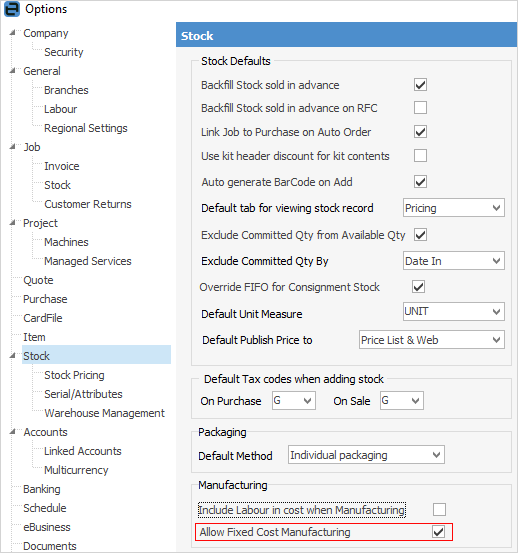

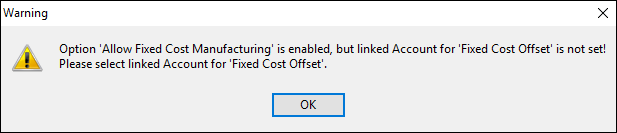

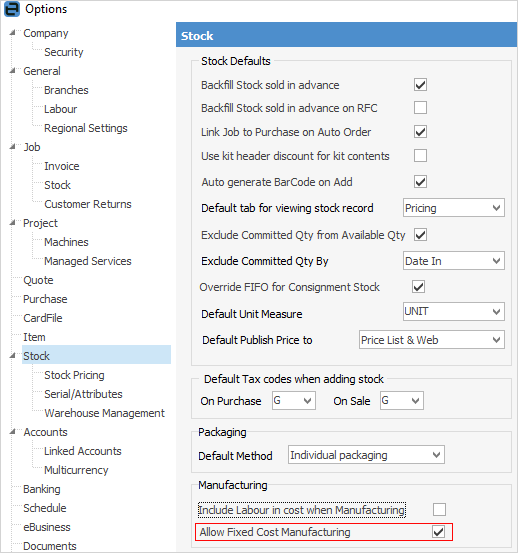

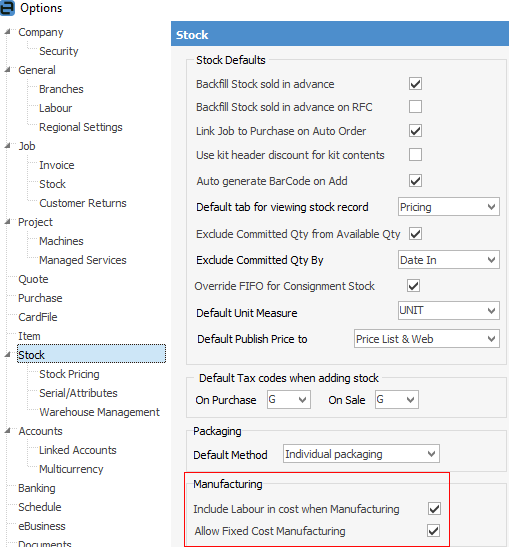

You must Allow Fixed Cost Manufacturing via Tools > Options > Stock first.

Jim2 will then take you to Tools > Options > Accounts > Linked Accounts, and the cursor will be positioned in the Manufacturing > Fixed Cost Offset field.

You will need to exit Options and set up your accounts first. |

It is highly recommended that this account be in the Cost of Goods area, as should a linked Manufacturing Labour Costs account. Using an account in the Cost of Goods area ensures that any offsets are accounted for within the current Profit and Loss period. If you are manufacturing over more than one accounting period, it is suggested that an Inventory GL account should be used (asset), but needs to be regularly reviewed and journalled out.

Next, on the ribbon, go to Tools > Options > Stock to enable fixed cost manufacturing:

Set up Stock

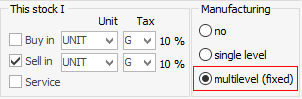

To enable multilevel manufacturing, add or edit an existing stock and tick multilevel (fixed).

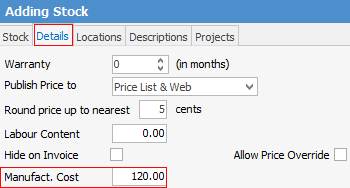

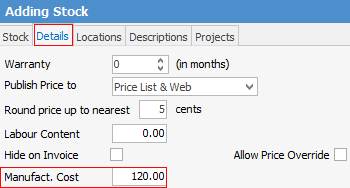

You can optionally set a default manufacturing cost in the Details tab of the Stock screen, which will be the default cost used on a Manufacturing job when manufacturing this stock.

The remainder of the setup is as for normal manufacturing, eg. a linked Manufacturing Item will be created where you can add the specific stock codes that will be used in the manufacture process. This is where the Bill of Materials is located.

Manufacturing Job

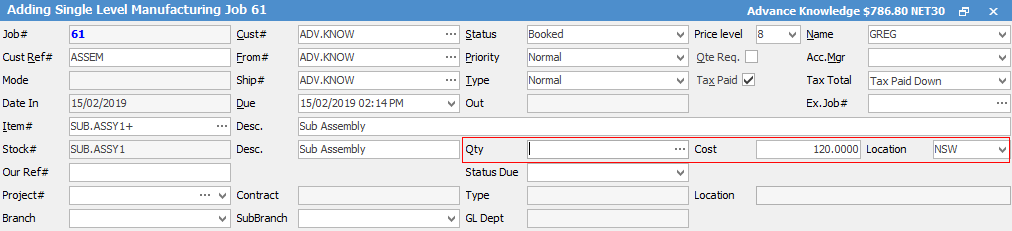

Once stock is set up for multilevel manufacturing, you can add a job and select the related Manufacturing Item. If the stock code is, for instance, SUB.ASSY1, then the linked Manufacturing Item would be SUB.ASSY1+.

The only difference from a standard (single level) manufacturing job is an additional Cost field.

It will be populated with the default cost specified in the manufacturing stock code (Details tab), and it will show the default cost of 1 unit. The cost can be changed at any time up until the point of selecting the Manufacture icon.

Regardless of how many products you are manufacturing, the cost figure is the cost to manufacture one unit.

The totals displayed on the Cost tab of the Manufacturing job have been updated to display the total fixed cost, the estimated actual cost, and the difference. You would expect this difference to be posted to the linked Fixed Cost Offset GL Account when you select the Manufacture icon.

Journals

When completing a Manufacturing job by moving to Finish status and selecting the Manufacture icon from the ribbon, the Fixed Cost Offset account will be used for the difference between the fixed cost set on the job and the actual cost of the stock codes used. For example, if all stock codes used in manufacturing are from purchase orders on Received, then the full cost will be offset.

When these purchase orders are set to Finish, Jim2 will reduce the offset account by the cost of the stock, as example 2 below.

An important difference, compared to single level manufacturing is, once the fixed cost stock is manufactured, its cost will not be affected by expense orders, thus enabling the stock codes to be used as parts in another manufacturing job.

Examples of Transaction Journals:

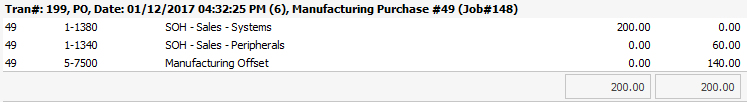

1.Stock was manufactured, and some of the purchase orders for the stock codes used in the manufacturing job are on Received status.

In this case, the stock on hand account for Systems goes up by the cost determined by the manufacturing job (which creates a manufacturing purchase order). The amount of $200 was set as the fixed cost on the manufacturing job, with $60 of the stock on Finished purchase orders, and $140 of the stock on Received purchase orders.

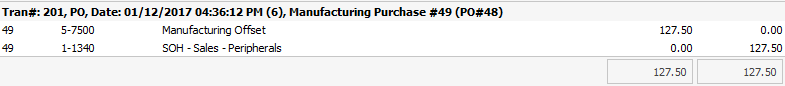

2.When the Received PO is moved to Finish status, any difference in cost will remain in offset, so the difference between fixed and actual cost in this example is $140 - $127.50, leaving $12.50 as a credit in the offset account, reflecting the lower actual cost:

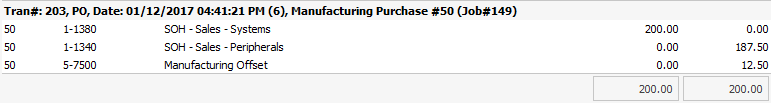

3.In the manufacturing PO below, all of the stock codes used in the manufacturing job were on purchase orders on Finish status. Using the same stock as in the previous example, you can see the flow.

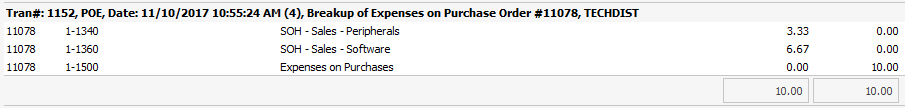

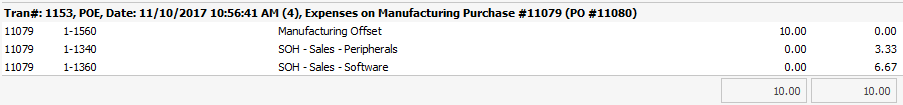

4.In this example, an expense order (eg. linked freight expense) was applied to the stock codes used in manufacturing:

and again, the manufacturing account was debited by the linked expense amount:

Fixed Cost Manufacturing Labour

Both single and multilevel manufacturing optionally allow the cost of labour to be included as part the total cost within the manufacturing process.

To allow labour to be considered as a cost of manufacture, in Tools > Options > Stock, Include Labour in cost when Manufacturing must be ticked and the Linked offset account set up (see above).

On the Details tab of the stock code, the cost of Labour is included in Manufact. Cost, along with the cost of any stock.

Any labour stock code that will be included in the manufacture will also need to have a Manufact. Cost, which represents the cost of providing one unit (normally an hour) of labour. This can be overridden on the job itself.

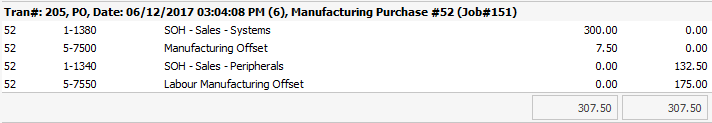

In the example below, a Labour stock code (with a Manufact. Cost of $175.00) has been included in the manufacturing job. The value of the Manufactured stock code increases by the value set on Manufact Job, and the Labour Offset accounts and Inventory accounts are credited.

You can see the Journal flow, below:

The Labour Offset will reduce the overall P&L expense for actual labour cost, as we are transferring this portion of wage expense to inventory value.

Further information:

Include Labour in Cost When Manufacturing