Jim2 Business Engine supports two methods of manufacturing: Single level manufacturing and multilevel (fixed cost) manufacturing.

Single Level vs Multilevel Manufacturing

Type |

Explanation |

Single Level |

▪Finished manufactured product put into stock on hand at exact cost of included parts (and labour, if configured via Options). ▪Any additional costs related to stock/parts used (from finished purchase order or expense order, etc.) are also included in the manufactured stock on hand cost, and flow through to COGS if stock is sold. ▪Must be the final manufactured product. ▪Can include stock/parts that are produced via multilevel manufacturing. |

Multilevel |

▪Finished manufactured product put into stock on hand at fixed cost at point of manufacture. ▪The cost difference between the fixed cost and actual costs of parts (and labour, if configured by Options) are offset to the linked fixed cost offset general ledger account. ▪Any additional costs related to stock/parts used (from finished purchase order or expense order, etc.) are offset to the linked fixed cost offset general ledger account. ▪Can be used in other manufacturing processes, including single level. |

Single Level Manufacturing

Single level manufactured stock is made up of Stock A + Stock B = Stock C. Single level manufacturing costs will be affected by expense orders.

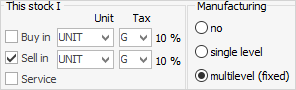

Consider what components are used to make a final product before selecting the Single or Multilevel (fixed) manufacturing type from the options in the stock header.

Once a manufacturing type is set for a stock code, it cannot be amended.

The manufacturing process in Jim2 involves:

a)The stock code that is to be manufactured.

b)The stock codes used in the manufacture process, including parts and labour.

c)A manufacturing Item, which is where the Bill of Materials is stored.

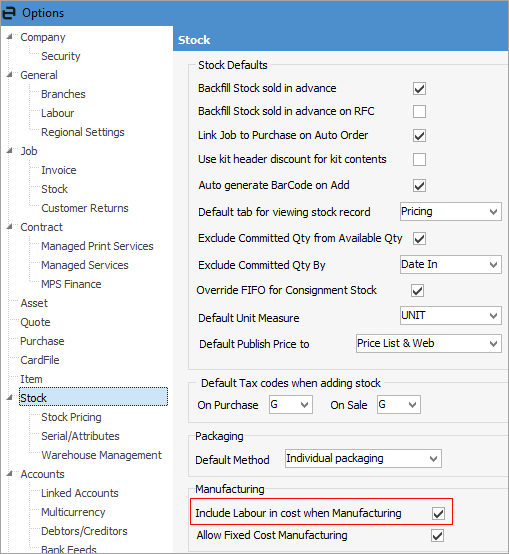

d)A manufacturing job, which is where the stock codes in point b) are consumed and manufactured into point a). The consumed stock codes in point b) are no longer available for jobs. The manufacturing job also records the actual labour used. Under Tools > Options > Accounts > Linked Accounts is a linked account called Manufacturing Labour Cost. This linked account is used to offset any labour included in the manufacturing cost. To enable this, tick Include Labour cost when Manufacturing in Tools > Options > Stock.

|

Only whole quantities can be manufactured, ie. it is not possible to manufacture, say, 4.5 of something. |

Multilevel Manufacturing (Fixed Cost)

Selecting the Multilevel manufacturing option enables choosing already manufactured stock (fixed cost) as a further ingredient in the manufacturing process, ie. use a finished product as a component to manufacture a further product, and so on, to produce the finished product.

Example: multilevel manufactured stock is made up of Stock A + Stock B = Stock C at a fixed cost, then Stock C + Stock D = Stock E.

This is possible because the cost of manufactured stock is fixed and set on the Manufacturing job. It is not updated when finishing purchase or expense orders of stock used in the manufacturing process, as compared to single level manufacturing.

▪When selecting multilevel (fixed), set the default manufacturing cost in the Details tab on the stock screen.

▪Jim2 uses a fixed cost offset account in the general ledger to account for the difference in cost between the actual costs and the set fixed cost. When completing a manufacturing job by moving to FINISH Status and selecting the Manufacture icon on the ribbon, the fixed cost offset account will show the difference between the fixed cost set on the job, and the actual cost of the stock codes used.

For example, if all stock codes used in manufacturing are from purchase orders on Received, the full cost will be offset. When purchase orders are set to FINISH, Jim2 will reduce the offset account by the cost of the stock.

▪Labour can be included as a cost of manufacture.

▪Unlimited levels of multilevel manufactured stock can be manufactured.

▪The cost of multilevel (fixed cost) manufactured stock does not fluctuate with changes in material and labour costs.

The last level of a manufactured stock can use either option: multilevel or single level manufacturing.

Multilevel manufacturing costs will not be affected by expense orders, thus enabling the stock codes to be used as parts in another manufacturing job.

▪Multilevel manufacturing involves any product that will be manufactured, then used in the bill of materials (BOM) of another manufactured product.

▪Fixed cost manufacture is how Jim2 manages the costing process. This means that each multilevel manufactured product will require a nominated fixed cost, approximating its asset value as a finished product.

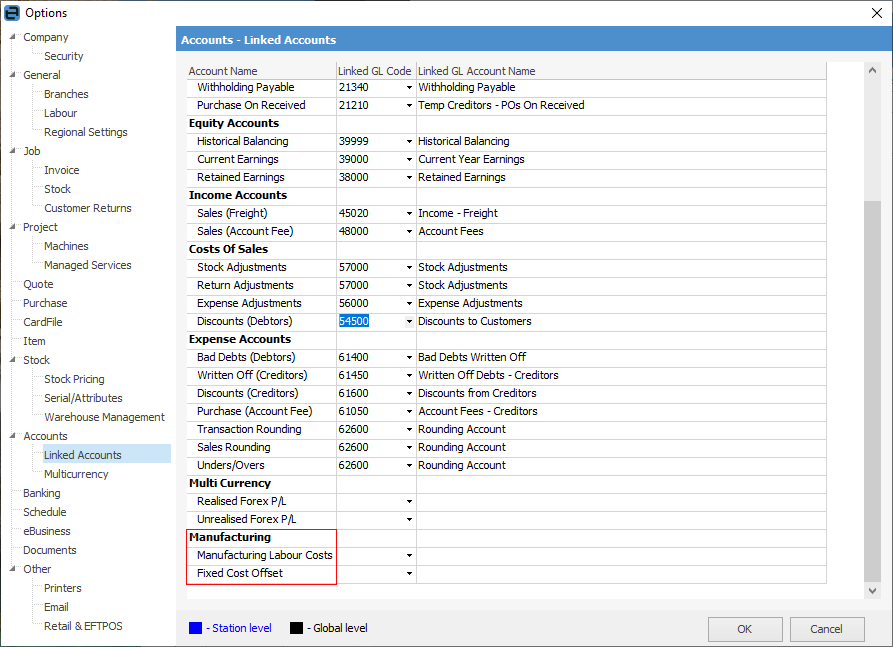

The variance (of real cost to fixed cost of manufacture) is then held in an offset account. The offset account needs to be nominated in Tools > Options > Accounts > Linked Accounts. The offset account must already exist in the General Ledger.

Further information

Set up and Use Multi-Level Manufacturing

Kitting v Packaging v Manufacturing