Some parts, such as fusers, can be refurbished two or three times, and re-used before being discarded. These refurbished parts need to be tracked to control the number of times they are refurbished, how long the refurbished parts last, and to track the cost of refurbishing.

The Setups:

▪On the ribbon go to Tools > Groups and add a new stock group for Manufacturing Components to separate the used stock to be refurbished in manufacturing, and another stock group for the Refurbished Stock (if required).

▪On the ribbon go to Tools > Setups and add a new stock location called MANU (for Manufacturing).

▪Add a new depleting stock record for the used part, eg. the actual part number with -U at the end (MFC1.PART1-U), and assign to the Manufacturing stock group.

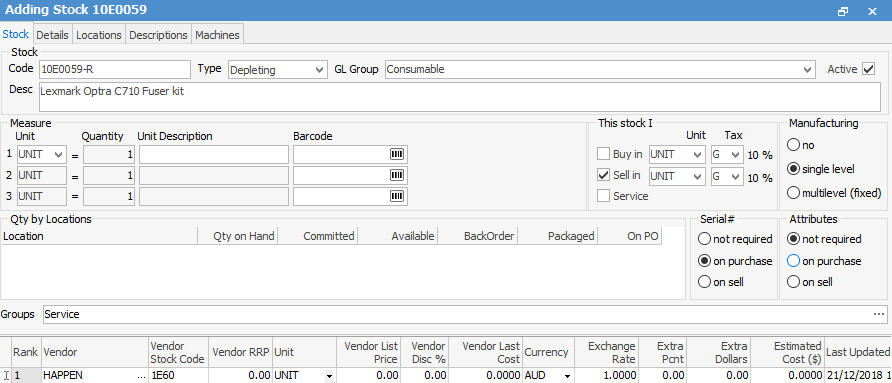

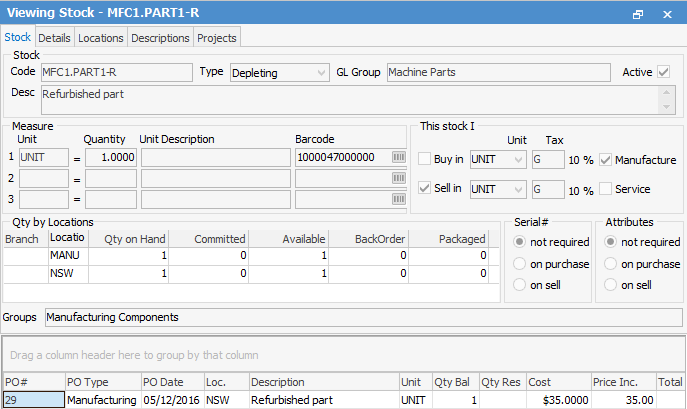

▪Add a new depleting stock record for the refurbished part, eg. the actual part number with -R at the end. Select This stock I, Manufacture, and Serial# on purchase. Serialising the refurbished part enables you to track how many times a part is refurbished, and how long it lasts. On the Vendor tab add your company as a vendor for inclusion in stock procurement.

▪When you save this stock record, the manufacturing Item will automatically be created as the stock code with a + sign at the end (refer to Manufacturing Jobs).

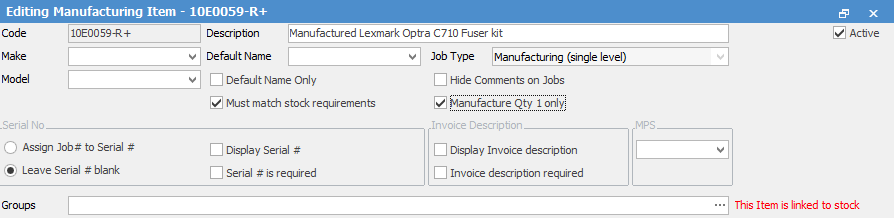

▪Edit the manufacturing Item, tick Manufacture Qty 1 only. You will only refurbish one used part on each manufacturing job, as different parts may need to be replaced during the refurbishment process, so this setting will be the default on manufacturing jobs.

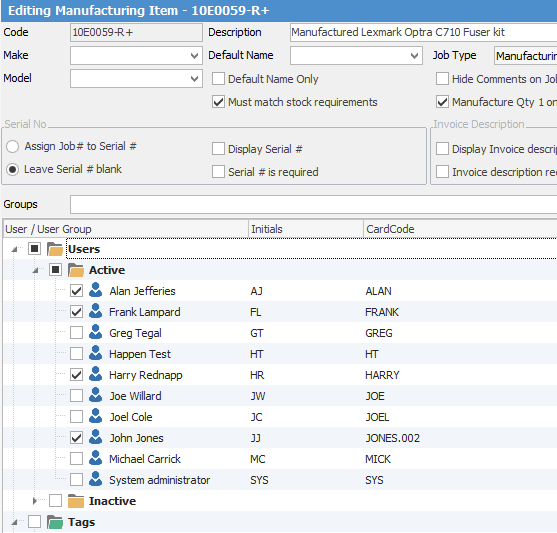

▪You should set a default name on the Item if not all staff can do the refurbishment. Tick the staff members who can do this type of work, so only they can have jobs using this manufacturing Item assigned to them.

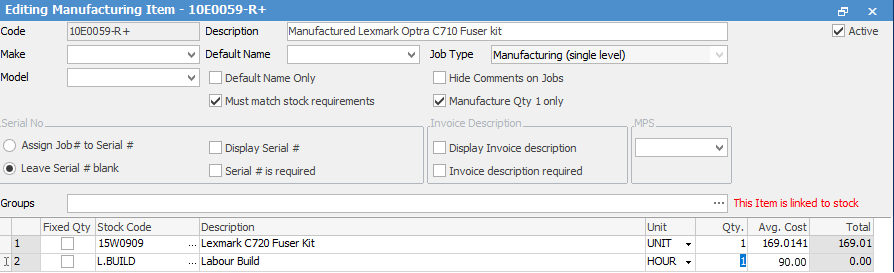

▪Select the Stock tab at the bottom left, and add the default stock that will always be included, ie. the used part to be refurbished, and an estimated amount of labour. Additional stock will need to be added to the manufacturing job as required.

If you want to include the actual cost of the labour to refurbish the part in the overall cost of the refurbished part, rather than just track the time taken, you need to add some additional setups as follows:

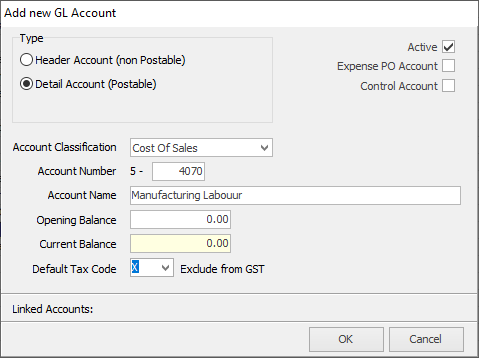

▪Go to Accounts > General Ledger > Cost of Sales and add a new 5-XXXX account for Manufacturing Labour. Set as a Detail Account only.

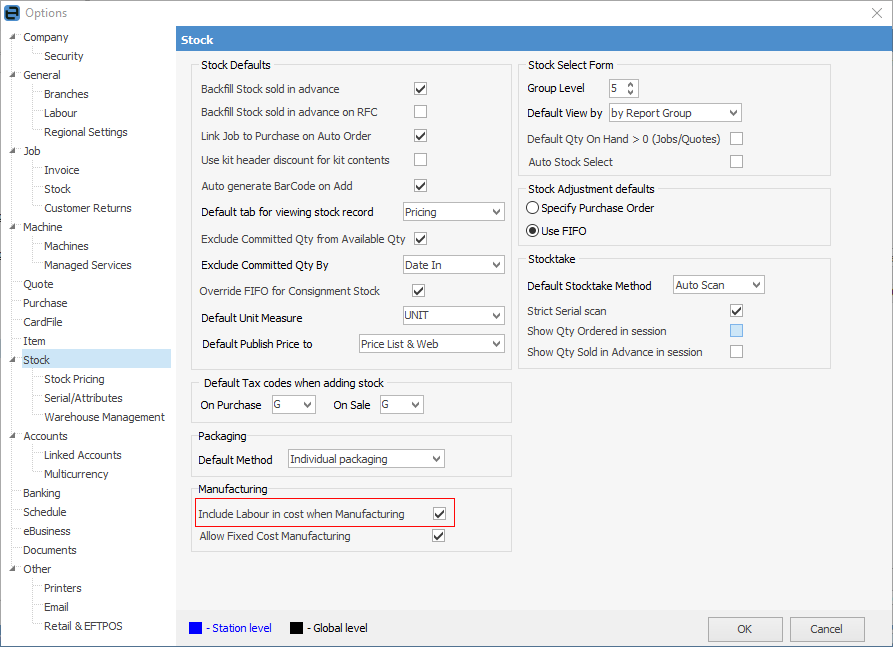

▪Go to Tools > Options > Stock and tick to Include Labour in cost when Manufacturing.

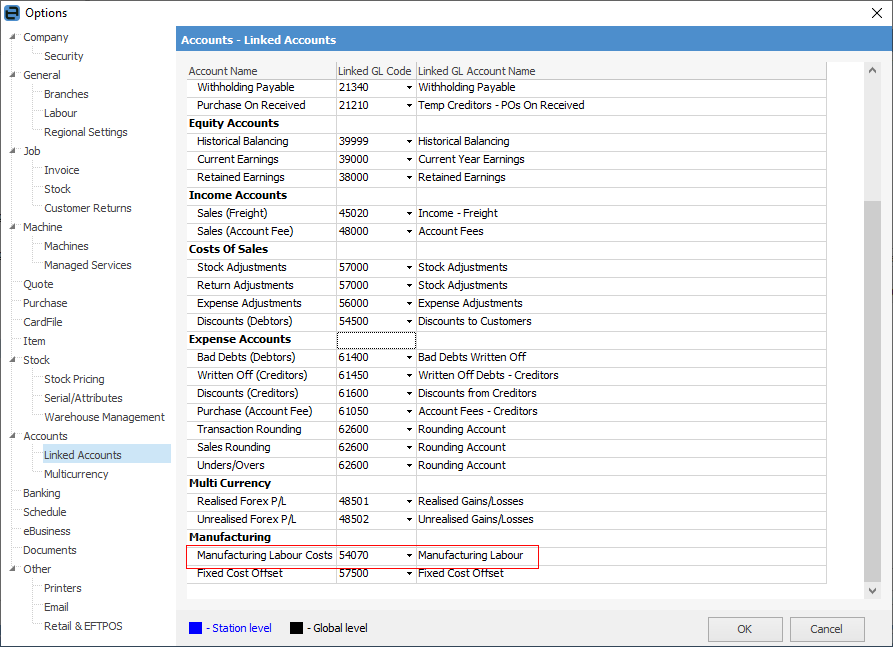

Then go to Tools > Accounts > Linked Accounts and enter the account you set up earlier.

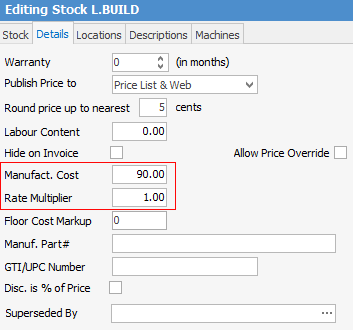

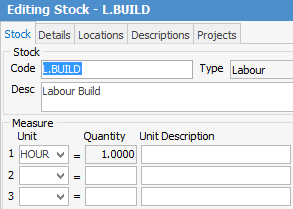

▪Edit the Labour stock record that you have selected on the manufacturing Item, go to the Details tab. In the Manufacturing Cost field enter the rate per hour that it costs to employ a person to do this work (not what you pay them per hour), enter a unit multiplier of 1, ie. it costs this much per hour, assuming your unit measure on the stock record = 1 hour, and a Labour Content of 1 (assuming that 1 x L.BUILD = 1 hour).

|

You may need to discuss calculating the cost per hour rate with your accountant. |

The Procedures:

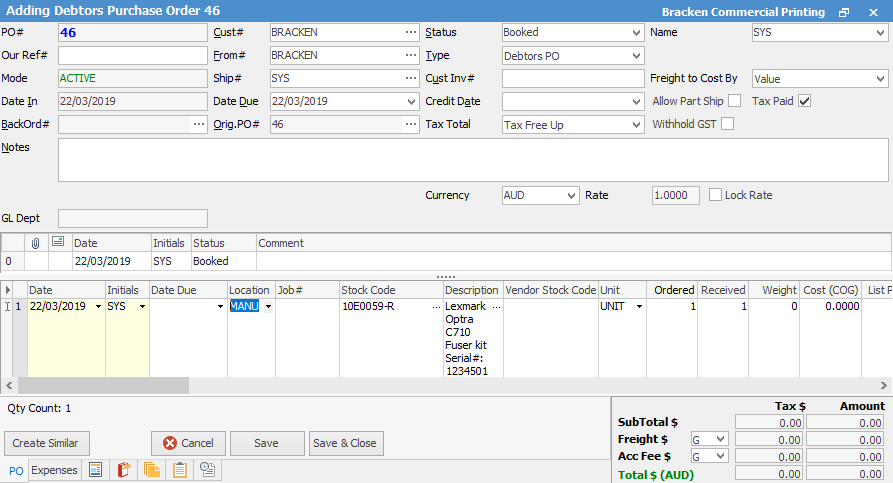

▪Add a Debtors PO to buy the used part into stock at zero value and zero COGS. This should be brought into the MANU stock location.

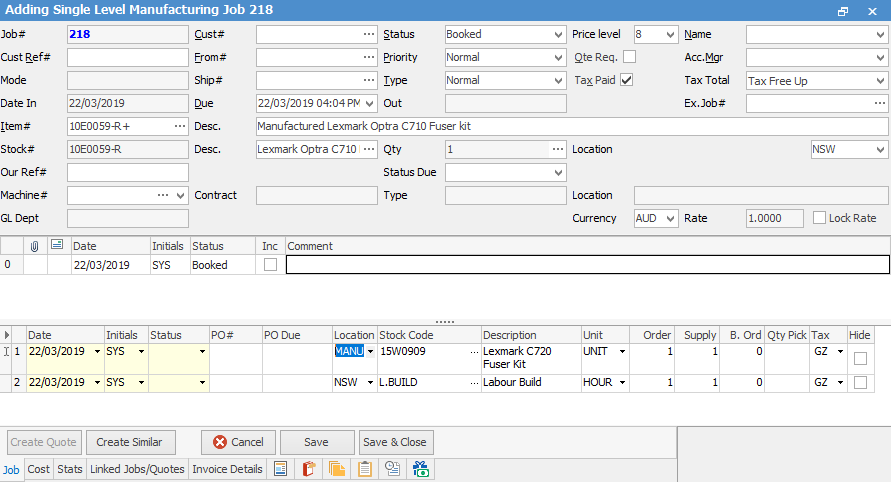

▪Add a manufacturing job with your company as the customer, and select the manufacturing Item for the part you are refurbishing.

▪Select the location where you want the refurbished part to go into stock when the manufacturing process is complete.

▪The Qty will default to 1 as set on the Item.

▪The stock set on the manufacturing Item will auto-populate the stock grid, but you need to check that it is being selected from the correct stock location, eg. the used part will be in the MANU stock location, and not the main stock location.

▪Add any additional parts used in the refurbishment – you must have this stock available in Jim2 before you can complete the manufacturing job.

|

No costs appear in the stock grid on the manufacturing job, but they are included in the cost of the manufactured stock. |

▪Press F7 and add the actual time spent to track the technician’s labour.

▪Edit the labour stock to reflect the cost of the actual time spent in the refurbishment process.

▪Change the status of the job to Finish, and Ready.

▪Click the Manufacture Job icon in the ribbon (it replaces the Invoice Job icon when you are working in a manufacturing job).

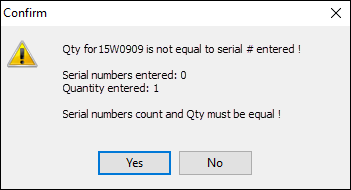

▪A warning message to prompt you to enter the serial number of the manufactured stock will appear – press OK.

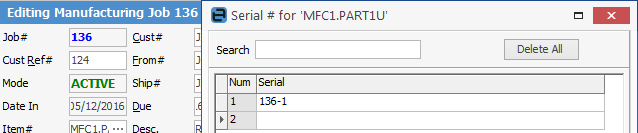

▪The suggested protocol for setting the serial numbers on refurbished parts is to use the manufacturing job number followed by -1 for the first refurbishment, -2 for the second refurbishment, and so on.

▪Click OK twice, then click the Manufacture Job icon again.

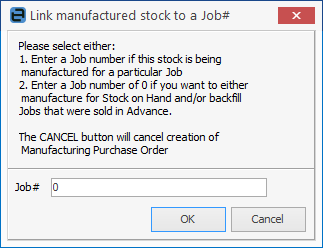

▪A screen will appear where you either nominate a job number if the part is being refurbished for a specific job, or enter 0 if it is to go into available stock.

▪Click OK to complete the manufacturing process and create a manufacturing PO.

Behind the scenes, a stock adjustment has effectively taken place, as the individual components in the stock grid on the job have been taken out of stock, the cost of the labour has been included in the process, and the finished refurbished part has been brought into stock on the manufacturing PO.

The transaction journal entry for the manufacturing PO shows how the parts and labour costs have been combined into the cost of the refurbished part.

Further information: